ZHONGYUAN has been committed to research and development exploration and experience accumulation in Cement plant power plant powder material lifting and conveying equipment since its establishment, and has provided intuitive [Powder conveying pump ] products to hundreds of customers!

1. LFB-I type material powder conveying pump is a new low pressure pneumatic conveying pump developed by our factory on the basis of introducing foreign advanced technology and aiming at various problems existing in different types of pneumatic conveying equipment in China in cooperation with building materials Institute. The product is widely used in power ash removal, cement homogenization and warehousing, conveying of various powder materials, with the highest consumption and complete sealing. No maintenance, air source can choose Roots fan, compressed air.

Ii. Working principle: The conveying material enters the pump body through the material sealing bin. The material in the pump body enters the diffusion mixing chamber through the main air pipe through the nozzle at high speed through the fluidized compressed air in the lower fluidized gas box of the pump body. The fluidized material in the pump body enters the diffusion mixing chamber and mixes with the air flow under the combined action of the material pressure in the material sealing bin and the negative pressure of the nozzle, and is carried by the air flow along the pipeline to the unloading point (inventory).

Three, single bin pump, negative pressure transport fly ash problems

1, power consumption, serious wear

As the bin pump adopts 0.4Mpa-0.6Mpa high pressure gas supply, the elbow pipe wear is serious. Wear through welding repair, frequent replacement, especially the discharge valve, feed valve, exhaust valve wear serious, often stuck, plus pneumatic three large parts damage maintenance costs are high, workers scramble to repair the pump body, high temperature, bad environment, high labor intensity.

2. Complex operation

Because the warehouse pump adopts automatic control of material level and time, the console connection is complicated and there are a few problems, involving electrical, thermal, ash removal overhaul three departments, multiple professionals to the ash field, delay the overhaul time, bring a lot of trouble to the management, difficult to ensure normal production.

3. The environment is bad

Due to the above reasons, in order to ensure the operation, there are many rush repairs, and the equipment leaks ash everywhere, endangering the environment in the factory and the surrounding people's living environment, and causing a great impact on civilized production.

4, affect the comprehensive utilization of fly ash

In order to carry out the comprehensive utilization of fly ash, enterprises have invested heavily in the development of fly ash production lines. However, due to the frequent damage of the conveying system, the normal production of the air separation equipment system cannot be guaranteed, and the ash pipeline cannot be sent out, which affects the user's ash supply and damages the enterprise image and interests.

5, affect the normal operation of sediment pond

Due to the design of ash and slag, bin pump damage, had to water rushed to the sludge pool, resulting in slag water is not enough, water supply tension, and because of the ash fineness is small, easy to cause network blockage, valve, ash pump pipe junction scrap, make the whole slag system loss serious.

6. Although the wear of negative pressure transmission is light, the fan gradually decreases with the air volume after several years of use, resulting in the phenomenon of ash delivery.

Four, the advantage of using the material powder conveying pump

1, the equipment investment is small, with a material powder conveying pump can replace two bin pump, reduce the equipment investment.

2. The gas pressure of the material powder conveying pump is 0.04Mpa-0.1Mpa, which reduces the gas supply pressure, saves gas consumption, and reduces the motor power.

3, reduce the maintenance cost. After the unified installation and commissioning of the system, there is no operation and almost no maintenance. The repairman only needs to check regularly.

4. Low pressure transmission, good sealing, reliable operation, no plugging phenomenon, perfect environmental appearance.

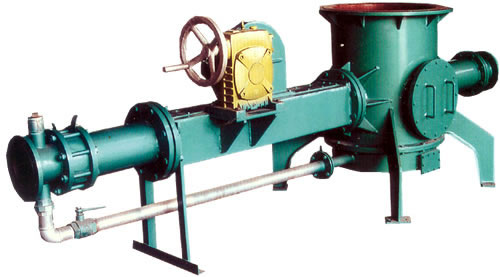

Five, structure and working principle

The material powder conveying pump is composed of diffusion chamber, pump body, movable air pipe, actuator and so on. The low pressure air enters the diffusion chamber through the inlet duct and the pump body. When the high speed air flow passes through the pump body, the material around the nozzle is vaporized. The air flow out of the nozzle and into the diffusion chamber forms local negative pressure in the nozzle and diffusion chamber, and the gasification material is inhaled into the feed pipe and lifted to the discharge point by the high speed air flow. The structural diagram is as follows:

Specifications, models and technical performance

| Model number | Transport capacity | Air consumption | Wind pressure | Air source motor power |

| M3/h | M3/min | MPa | Kw | |

| 75 | 0-8 | 5-8 | 0.03-0.1 | 11-30 |

| 100 | 5-15 | 6-20 | 0.03-0.1 | 18.5-45 |

| 150 | 10-25 | 10-30 | 0.03-0.1 | 22-55 |

| 200 | 25-35 | 20-45 | 0.03-0.1 | 30-75 |

| 250 | 40-55 | 40-70 | 0.03-0.1 | 45-90 |

| 300 | 50-70 | 70-100 | 0.03-0.1 | 55-120 |

| 400 | 70-100 | 92-150 | 0.03-0.1 | 45-350 |

Some users

How to make ZHONGYUAN [Powder conveying pump ] service upgrade create greater customer value and provide innovative products for the society is the direction that ZHONGYUAN people are committed to pursuing! !